Knowing that you should make an effort to learn about the best soundproof insulation you could use in walls and ceilings.

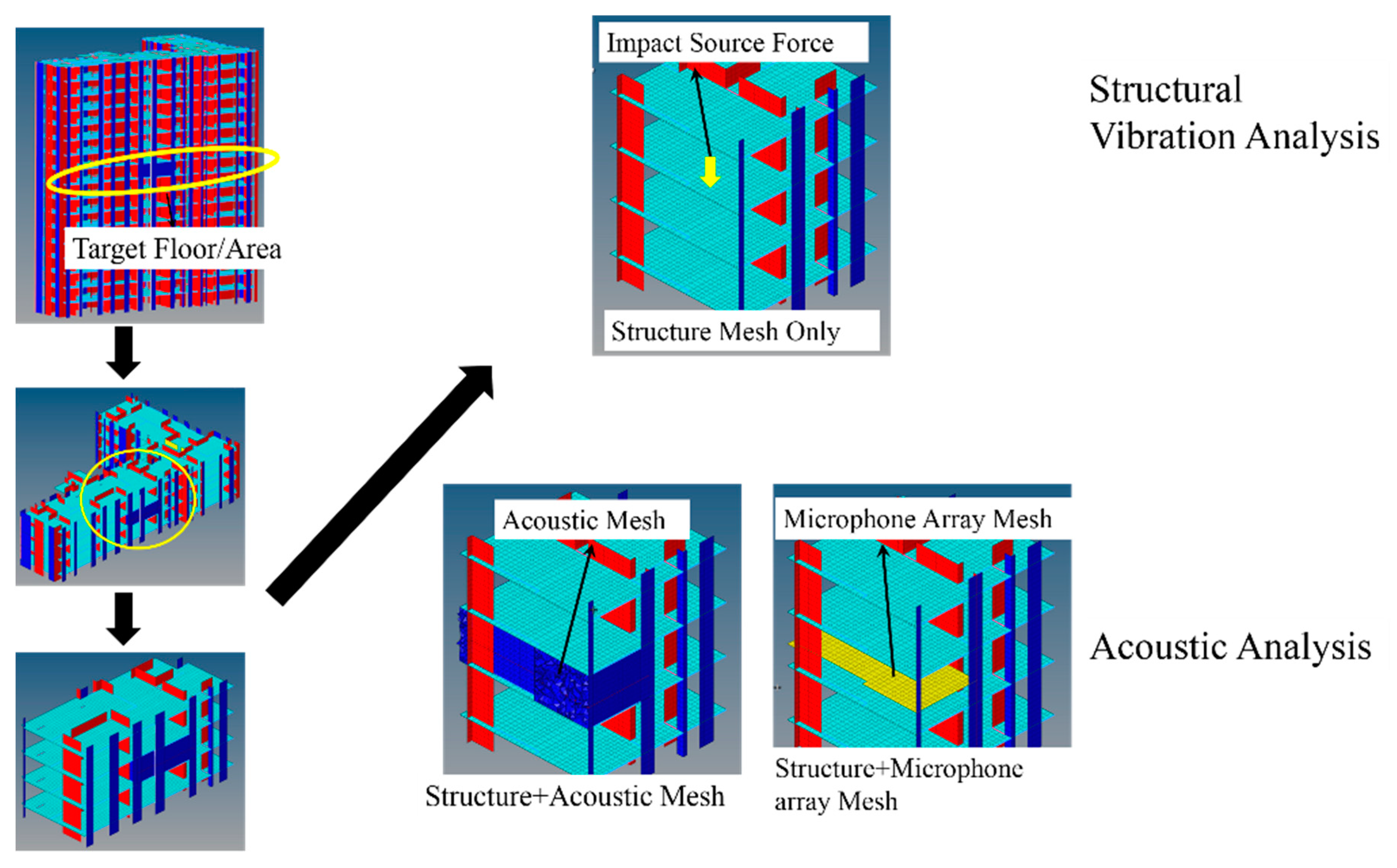

Sound insulation properties of concrete walls and floors.

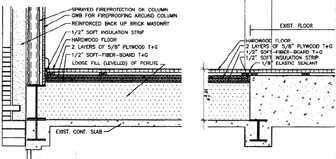

When it comes to concrete and soundproofing you should always focus on coating the walls with a layer of noise reduction materials first.

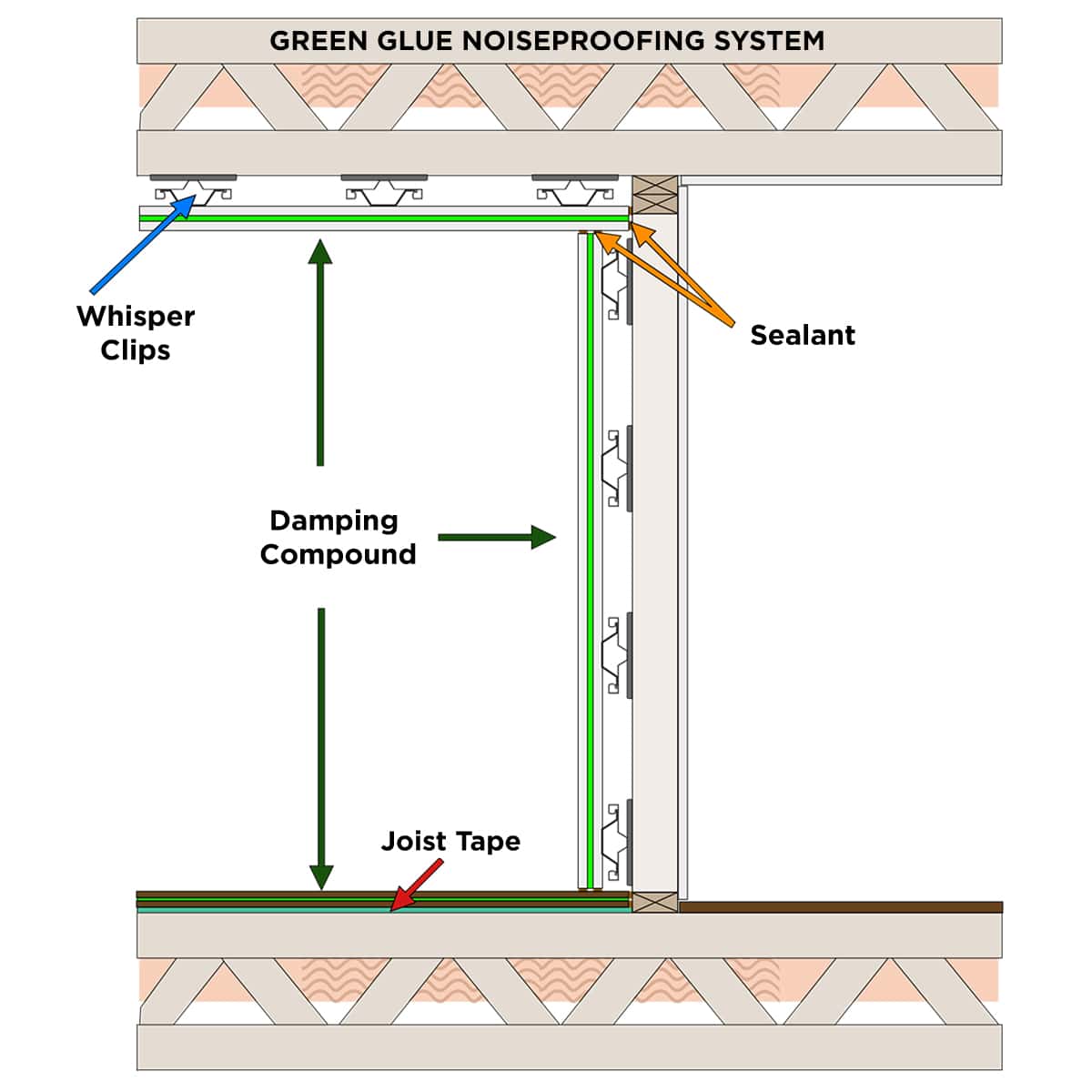

Insulating products are a key component of any soundproofing project.

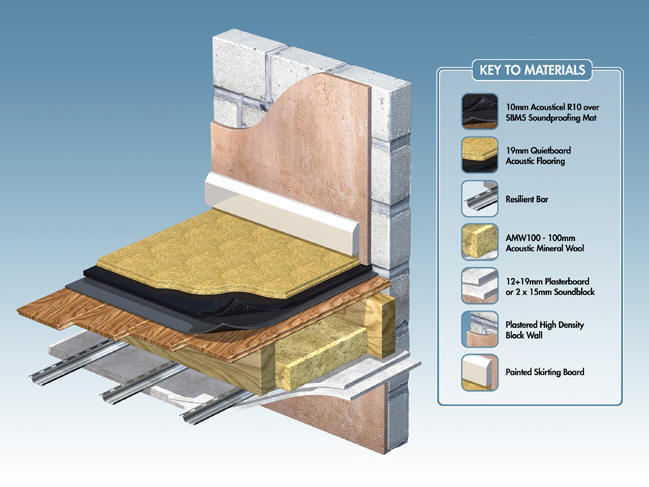

Using a combination of isolation absorption and mass a plastered 100mm blockwork wall can be upgraded to meet the building regulations.

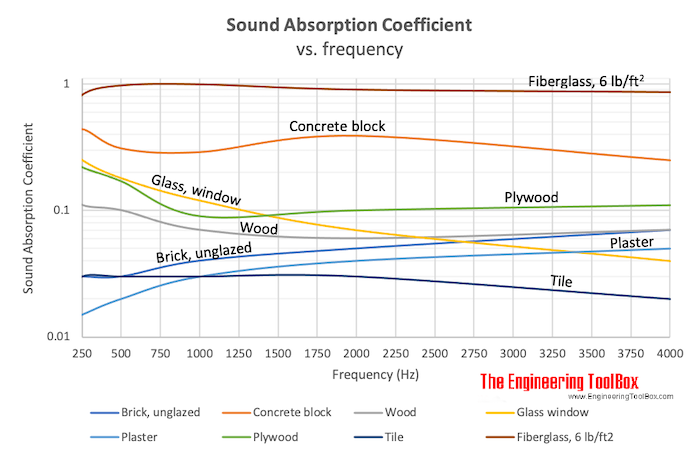

Any hard surfaced material whether it be polished concrete or tiled concrete will produce a low impact sound insulation.

Non floating floors if a floating floor is not an option then the best method of insulating the floor against impact sound is to provide soft resilient floor coverings.

The need for additional finishes is minimal thereby reducing capital and ongoing maintenance costs.

Noise control in buildings for residential use in england and wales is regulated using approved document e.

Here we talk you through the process using rockwool products.

Isolation an independent timber or stud frame should be constructed at least 10mm away from the existing wall.

The more the concrete weighs or the denser the concrete the more sound insulation the greater sound transmission loss rating.

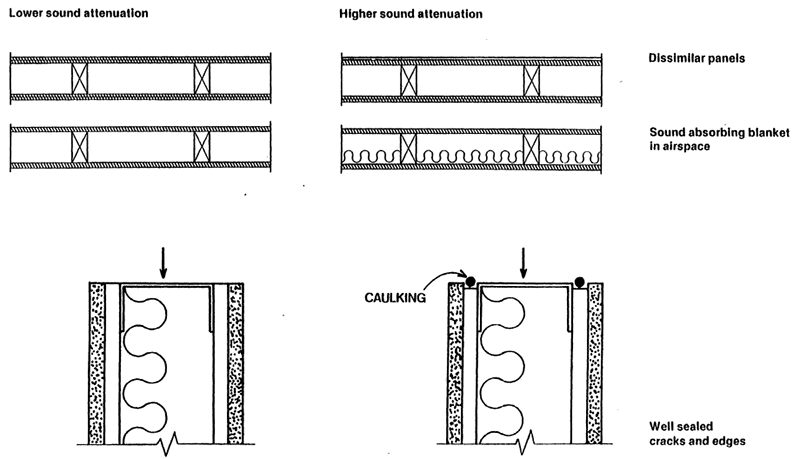

First we have to make the distinction between insulating products and other soundproofing materials there are many materials you can attach to your wall to approximate the way insulating products work.

Simply put walking down a painted dense high psf weight concrete hallway floor ceiling walls in capped boots will be very noisy but the person in the next room may not hear you very well if there are no.